BS476 Parts 6 and 7, Flame Retardant Paint and Varnish - to coat ceilings and walls to achieve surface spread of flame resistance.

Low odour, water based fire paints and varnishes also meet the British Standards - known as Class 1 and Class 0 - equivalent to European BSEN 11925, BSEN 13823. Easy application Emulsion Paints, even over existing paint.

We can save you money and time by giving you the simple, straightforward rules for meeting the Fire Regulations. Just call us or us on 01626 872886 for instant help and advice.

Price Match Guarantee - we will not be beaten on price. Call 01626 872886 for instant Quote.

Click here to look at the product, check prices and Order in our Fire Paint Shop

Testing to Classes 1 and O - no flames.

Q. BS476 Parts 6 and 7 - what are they?

A. They are the UK 'surface spread of flame' Test Standards (nothing to do with 30 or 60 minutes)

Click here to look at the product, check prices and Order in our Fire Paint Shop

BS476 Part 7 – Test to determine the Classification of surface spread of flame - UK Class 1, Euroclass C.

Class 1 conforms to BS 476 Part 7 and is the performance normally required for wall and ceiling linings. To achieve Class 1 BS 476 Part 7 classification, the spread of flame must not be more than 165mm in 10 minutes.

Click here to look at the product, check prices and Order in our Fire Paint Shop

BS476 Part 6 - Fire Propagation test to determine a surface spread of flame Fire Propagation Index number - UK Class O, Euroclass B.

Class 0 is a more stringent requirement to BS 476 Parts 6 & 7 and is normally required in higher risk areas of a building, such as escape routes and staircases. Class 0 BS 476 Parts 6 & 7 classification includes the requirements of the surface spread of flame (Part 7) but also Part 6, which is known as the 'Fire Propagation Index', a measure of the heat released when timber burns. Timber achieving a Class 0 specification must achieve a Fire Propagation Index of 12 and a Sub-Index of 6.

On most materials, to comply, you will need at least one coat of Intumescent (swells in heat) Paint or Varnish, plus at least one coat of Flame Paint finish.

Click here to look at the product, check prices and Order in our Fire Paint Shop

What to Buy: click USES to determine the number of coats or call us on 01626 872886 .

For a colour finish: Colour Chart Click Here.

PRS Intumescent Paint - apply between 1 and 4 coats, or according to the Fire Standard required by your Building Inspector.

PRS Flame Paint Finish - apply 1 to 2 coats, according to durability - indoors/outdoors, high/low wear finish required.

Click here to look at the product, check prices and Order in our Fire Paint Shop

BS476 Paints and Varnishes - Benefits: intumescent paints and water based top coats

* water based

* low odour

* no solvents

* thin coats

Fire Paint and Varnish typical coverage: click SHOP to see the details

For a colour finish:

PRS Intumescent Paint - 8 square metres per litre, 20 square metres per 2.5 litre (3.25kgs) pack.

PRS Flame Paint Finish - 8 square metres per litre, 20 square metres per 2.5 litre pack.

Fire Paint and Varnish Prices, Discounts and Delivery: call 01626 872886 for full details

Prices - some prices are lower than given above when purchased in larger pack sizes, see SHOP to see the details

Discounts and Trade Sales - call us for details

Delivery - Same day dispatch, Next Day Service, UK Mainland - £10 plus VAT

Click here to look at the product, check prices and Order in our Fire Paint Shop

Fire Paints and Fire Varnishes are suitable for:

1. Meeting BS476 on Softwoods, Hardwoods, MDF, Chipboard, Melamine faced sheet, Bamboo, Steel.

2. Interior and Exterior BS476 Standards: Fire Retardant products for doors, decking, bar-tops, paneling, cladding and floors.

3. BS476 finishes over Painted surfaces, Varnished, Stained and Unpainted surfaces.

4. BS476 paints and varnishes in Clear finishes, White Finishes or Coloured Finishes.

5. Ideal for meeting BS476 Loft Conversions, Hotels, Boarding House, Flats.

6. Fire Doors, and door upgrades to modify existing solid wood doors to 30 minutes (FD30) Standard.

7. BS476 requirements for Exhibition Stands, Shopping Centre Kiosks, Night Club Bars, Restaurant Bars, Shop Fixtures, Shop Shelving.

Speak to us now for free help and immediate pricing - Tel: 01626 872886

Fire Certificate of Supply

Certificates for: Class O and Class 1, 30 minutes, 60 minutes and 90 minutes Fire Resistance, Timber and Steel.

Colours: Clear Varnish and all B.S. and RAL Colours available ex stock for Next Day Delivery. For a RAL Colour Chart Click Here.

Finishes: Matt, Eggshell, Gloss and Metallic.

Doors: Click here for - Guidance Notes on upgrading Doors

Click here to look at the product, check prices and Order in our Fire Paint Shop

What you really need to know about Fire Retardant Paints:

TYPES OF PAINTS and VARNISHES - there are two types of Fire Paint and Fire Varnish:

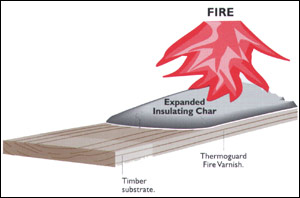

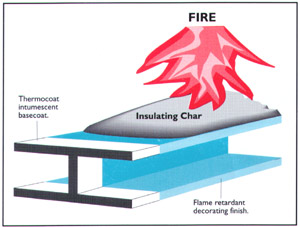

Fire Retardant Paints and Fire Retardant Varnishes are used to stop the spread of flame on a surface by releasing an inert, safe gas and are tested to assess their effectiveness under BS 476, part 7. These are used in all rooms for walls and ceilings. They are also used on top of base coats of the Intumescent (swells up in heat) paint or clear varnish, because these base coats are too soft to be durable if exposed to wear or high humidity.

Intumescent Paints and Intumescent Varnishes swell and char when exposed to fire. They work by insulating the building material from heat. They are softer, so require a top coat of Fire Retardant Paint or Fire Retardant Varnish. They are always needed as base coats on combustible materials, like wood and on products that warp in fire, like steel.

Click here to look at the product, check prices and Order in our Fire Paint Shop

BS476 FIRE TEST STANDARDS - there are three relevant fire test standards

Class 1 - requires no surface spread of flame.

This is the Standard normally required for walls and ceilings.

Class 0 - is an additional level of protection for walls or ceilings where limited combustibility is required in high-risk areas, such as escape routes.

To comply materials must have a Class 1 Surface Spread of Flame and low fire propagation index in accordance with BS 476 Part 6. This test checks that the coating does not add to the heat or intensity of the fire.

Fire Penetration Resistance - 30 minutes or 60 minutes.

Intumescent Coatings are used to prevent the penetration of fire through a structure for a specific period in accordance with BS 476 Parts 20 - 23 1987. Such coatings are given classifications for specific periods of time, such as "30 minutes". Intumescent systems are available for protecting structural timbers, steel and plasterwork (including plastered and plaster boarded walls and ceilings).

Click here to look at the product, check prices and Order in our Fire Paint Shop

FIRE PAINT AND VARNISH CERTIFICATION - why you will need a Certificate of Supply

A Fire Certificate of Supply can be issued for each Project. This is essential if you have to satisfy your Insurers, the Fire and Building Control Authority and for Client Records. Without a Fire Certificate you may be vulnerable to prosecution in the event of a fire. We cannot issue a Certificate of Supply if we have not produced a Specification in the first place, so please do not buy paints without asking for a Specification.

FIRE PAINT COLOURS

BS and RAL Colour Range, plus five Metallic Finishes, plus clear Varnish. For a RAL Colour Chart Click Here.

FIRE PAINT FINISHES

Matt, Eggshell and Gloss.

FIRE PAINT DRYING TIMES

Consult the individual product pages - in general Intumescent base coats require at least 4 hours to dry between coats and will not tolerate high humidity or rain. Finish coats cannot be applied to the final Intumescent coat for up to 10 hours. Gloss Finish paint requires 12 hours between coats. All other paints in the range behave like normal water based finishes, subject to the drying and surface conditions at the time of application.

How to comply with Class 0 and Class 1 - comply with both in a single system

For timber and timber products, painted or unpainted, EXCEPT DOORS.

Colour coating:

1. Timbercoat Intumescent - 1 coat, by brush, roller or spray - 8 square metres per litre per coat.

2. Flame Paint Retardant finish - two coats, by brush, roller or spray - matt, vinyl or silk, gloss, eggshell or metallic - 8 square metres per litre per coat.

Clear coating:

1. Fire Intumescent Varnish - two thin coats by brush, roller or spray - 6.5 square metres per litre per coat.

2. Fire Varnish finish - one or two coats by brush, roller or spray - 10 square metres per litre per coat.

Over coating old paint layers:

For plasterboard, plaster, brick and concrete products, that have a thick layer of old, non-retardant paints.

1. Wallcoat - one coat, by brush, roller or spray - 8 square metres per litre per coat.

2. Flame Paint finish - two coats, by brush, roller or spray - matt, vinyl or silk, gloss, eggshell or metallic - 8 square metres per litre per coat.

Note - the second coat can be a Flame Retardant Anti-Graffiti or Hygiene Paint.

How to provide 30 - 60 minute protection

For steel and cast iron products, painted or unpainted, EXCEPT DOORS.

1. High Build Primer - apply one coat by brush, roller or spray - 7 square metres per litre - 150 microns (wet).

2. Intumescent Steel Paint - typically, apply one coat by brush, roller or spray for up to 30 minutes protection, two coats for 60 minutes protection - at about 2 square metres per litre per coat. This is only a very general example - steel paint coverages need to be calculated by us for each different section size and then converted to a paint volume. This is a free of charge service.

3. Flame Paint Top Coats - to cover and protect the Intumescent paint where either it is to be temporarily exposed during Construction, or left permanently exposed after completion. Intumescent Paint can ONLY be used alone where it will be protected by coverings or casings, and will always be inside a dry, indoor environment.

A typical brush coating can be applied at up to 600 microns thick (wet) or by sprayer at up to 1200 microns thick (wet). A simple plastic wet film gauge is supplied with the paint.

500 microns wet = 2 square metres per litre = 0.5mm thick

1000 microns wet = 1 square metre per litre = 1mm thick

Steel Specification and Costing

We will convert your steel measurements, or information from a Plan into surface areas to be treated. This will allow us to calculate the thickness and volume of Intumescent Fire Retardant Paint required.

You can download a copy of the Steel Calculation form and drawings of the different types of steels commonly used in building here - Steel Form and Steel Types.

The crucial information is the thickness of the steel - this affects the thickness of the Intumescent Paint coating required to meet a particular Standard.

Doors

Sometimes it can be cheaper to buy factory built Fire Doors. For multiple doors and Historic Buildings, where doors must be saved, please give us a call to discuss your options. We will need exact details of the construction of each door and some photographs would help. Give us on call on 01626 872886 for FREE help with your Fire Door Specification.

SAFE MINIMUM THICKNESS OF WOOD - to meet the 30 Minute Standard

A minimum of panel thickness of 10mm and 16mm is required, for our fire paint and fire varnish products.

When using Ultra Door Protection for upgrading standard doors to 30 minute fire doors, it must be used as part of an overall program to include intumescent fire/smoke seal and lock, hinge and door closer Intumescent protection card, or as Specified by your Building Inspector.

As a general guide, uprating is likely to include the following;

1. Preparation of the doors to take intumescent fire/smoke seals and lock, hinge and door closer intumescent protection cards. We can offer surface mounting Intumescent Seal Strips, which are self adhesive and mount inside the door frame. This type of seal enables you to avoid removing the door to cut slots.

2. Four coats of Ultra Door Intumescent Fire Paint or 3 coats of Varnish base, followed by two top coats of Flame Paint or Flame Varnish Finish (Eggshell or Gloss).

3. Additional panels or Veneer may be required to meet the minimum thickness requirements - we can manufacture this for you - please ask for a Quotation.

Click here for - Guidance Notes on upgrading Doors

Click here to look at the product, check prices and Order in our Fire Paint Shop

Free Advice - we supply free specifications and product quotations

Speak directly to us about your Fire Retardant needs: 01626 872886

Please do not take a risk and simply buy products without a clear specification from an expert. You may not be able to obtain a Fire Certificate of Supply in those circumstances.

'Fire Paint' is a general term rather misleadingly used to cover both Fire Resistant Paint, used as a top coat to protect the Intumescent Paint beneath and Intumescent Paint or Intumescent Varnish, which are both fairly soft coatings used as primers. Class 1 and Class O are Classifications used regarding fire action on the surface of the paint, whereas 30 Minutes and 60 Minutes describe the period of protection given by the underlying Intumescent layers of Intumescent Paint or Intumescent Varnish against fire penetration.

We can provide an Intumescent Paint price based on the thickness of the wood or steel to be protected, and a separate price for the Fire Rated paint used as a top coat, which acts as a retardant fire layer, producing an inert gas to protect itself.

I Steel Paint I Over Coating Old Paint I Loft Conversion I Colour Charts I Home Page

Use any of our Shopping Pages to place goods in your Shopping Cart - they all use the same Shopping Cart system.

Click to view your Shopping Cart

or continue shopping by clicking on one of our Shops below.

OUR SHOPPING PAGES

Property Repair Systems

TEL: 01626 872886

Contact | Privacy Policy | Returns Policy | About the Author

Site written by: David Moore

David Moore, B.A. (Hons.), C.T.I.S., C.R.D.S. Technical Author

Google+

Other Property Repair Systems Sites:

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.epoxy-info.co.uk - epoxy resins for repairing wood, concrete, brick and stone

www.fire-door-paint.co.uk - upgrade doors to 30 minutes fire resistance

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber.org.uk - systems of repair, with step by step methods

www.timber-repair.co.uk - how to repair timber beams